Today, printing on clothes is an inexpensive and easy way to create a really stylish and unique wardrobe item to attract attention and be unique. It is interesting that the first technology of drawing on fabric appeared several centuries ago. How it was, and what has changed since then, we will tell in this article.

The work of the hands of masters. Middle Ages

The earliest experiments with printing on clothing were in the Middle Ages, when monks and artisans used a variety of techniques to decorate fabrics. One of the early methods was stamping, where a craftsman manually applied paint or pressed an image onto the fabric using a wooden or metal stamp. It was a very time-consuming and limited technique that did not allow for the creation of detailed or complex drawings.

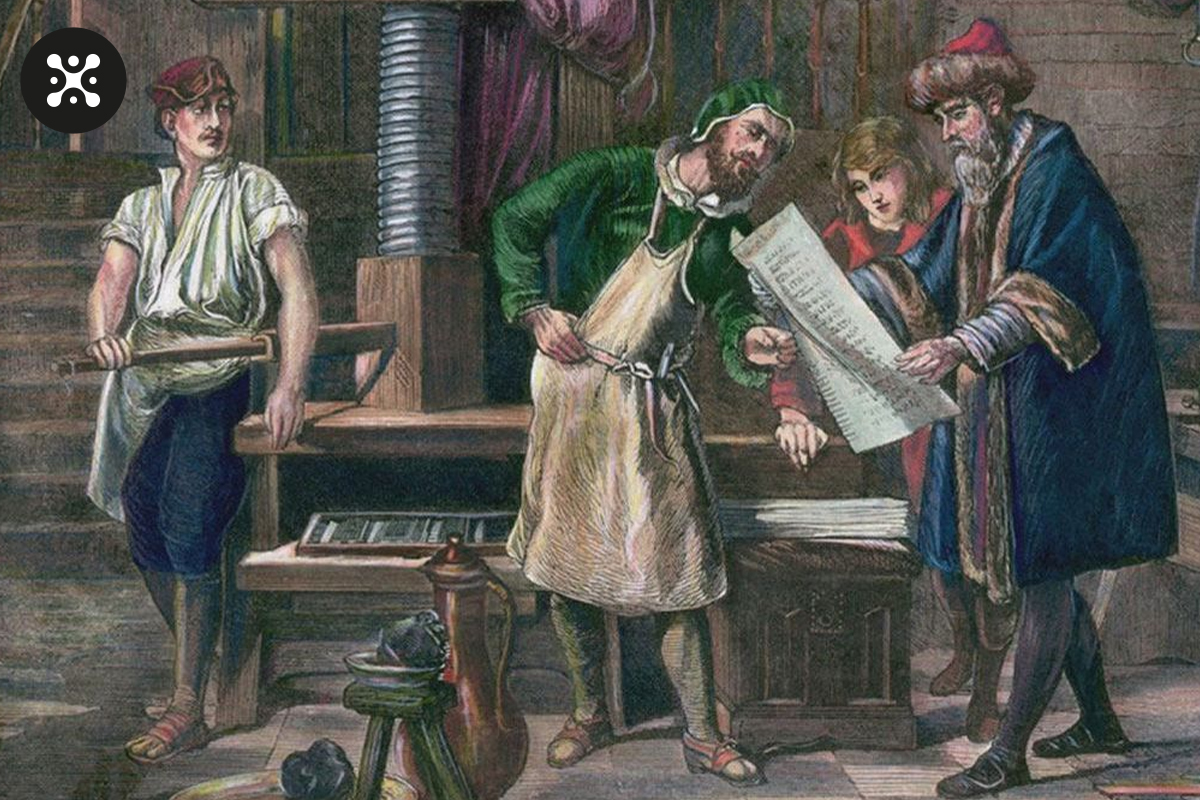

Invention of the printing press

The next significant stage in the history of printing on clothes is associated with the invention of the printing press by Johann Gutenberg at the beginning of the 15th century. This invention was revolutionary in the printing process. Gutenberg was the first to use piles of wooden printing blocks on which he engraved images or text. These blocks were dipped in paint and then applied to the fabric. This method made it possible to make more identical copies of the image. The use of printed fabric became popular among the upper class, which opened up new opportunities for luxurious and innovative designs. The flowering of the textile industry began.

Source: https://24tv.ua/tech/hto-takiy-yogan-gutenberg-chomu-google-prisvyativ-novini-tehnologiy_n1597696

The era of textile prints. 18-19 centuries

In the 18th and 19th centuries, textile printing experienced an era of rapid development. Manufacturers began using large rollers with engraved images to create repeating designs on fabrics. One of the innovations of that time was the production of calico fabrics, which were printed using wooden rollers. This process was called "calico printing" and allowed manufacturers to create various and multi-colored designs on fabrics. This type of printing has become especially popular in the production of fabrics for dresses.

Serial production and lithography

At the beginning of the 19th century, the era of serial production began. An important step in the development of textile printing was the invention of lithography, a printing method in which an image is drawn on a lithographic stone and then reproduced on paper or fabric. Lithography made it possible to create more complex and detailed drawings. This period also saw the development of new types of fabrics, particularly silk and cotton, which proved to be ideal for printing. Lithographic techniques were used to create repetitive and meticulously detailed designs, from simple geometric motifs to complex caricatures and landscapes. These techniques made it possible to cheapen and speed up the production of textile products, making decorated clothing more accessible to the general consumer.

Screen printing

In the 20th century, a revolutionary technology of printing on textile products appeared - screen printing. This method used a stencil that was placed on top of the fabric and paint that was pushed through the exposed parts of the stencil. One of the advantages of screen printing is its versatility and ability to be used on different types of fabrics, including cotton, polyester, linen and other materials. Screen printing has greatly facilitated the production of mass batches of printed clothing. It also encouraged the proliferation of individual and creative designs, as manufacturers and designers were given more freedom to create unique patterns and styles.

Digital printing. From the end of the 20th century to the beginning 21 st.

In the 1970s, new technologies for printing on clothes appeared on the market, including sublimation printing. It allows you to apply vivid and detailed images to various textiles, including t-shirts, jackets, towels, flags, etc. The technology itself is the application of an image on synthetic textiles. In the process, the dye is transferred to the fabric upon sharp heating to 180-220 ° C: The dye changes from a solid state to a gaseous state, bypassing the liquid phase. This technology is suitable for fabrics that contain at least 60% synthetics.

Today, there are many different methods of printing on clothes: digital printing, thermal transfer, silk printing, and others. Each has its advantages and disadvantages. Printing on clothes can be done on: cotton, polyester, nylon, silk, etc.

Digital printing on textile products represents the modern stage of development of printing technologies. It arose as a result of the growth of computer technologies. The image is transferred to the fabric directly from the computer, without the need for other intermediaries. Digital printing provides endless possibilities for detailed images on clothes.

DTF - technology - is the most modern technology of applying images to clothes. With its help, we at Dubhumans realize the coolest and weirdest ideas - our own or our clients'. Thanks to this technology, images are transmitted in detail and clearly. As in a high-quality digital photo. For our collections, we use high-quality fabric, have our own tailoring workshop and make sure that our printer prints the best possible on the film, which we then transfer to the client's clothes. You can take a closer look at options for T-shirts, suits, sweatshirts or hoodies on our website. And our manager will help you choose the size and color.

Interesting facts about fabric printing today

- Another area of development is interactive and electronic printing. This allows electronic components such as LEDs, sensors or even microcontrollers to be embedded directly into textiles, creating "smart" clothing. This can be used to create interactive models that respond to movements or even interact with the environment.

- Biomaterials. An important aspect of innovation in digital printing is the development of biomaterials and inks that aim to reduce the environmental impact, these materials decompose naturally after use, contributing to the creation of more environmentally friendly textiles.

As you can see, technologies are developing every day and today it is very easy to diversify your image with the help of printed clothes. After all, a unique thematic print will distinguish you from the crowd - 100%. You can view the options of our designer Dubhumans in our online store or come up with your own. It's easy to be in the trend, hurry up!